上一张

下一张

Function: Ultra-high-definition detection capability of more than 10m/s, accurate quantification of pipeline defect characteristics.

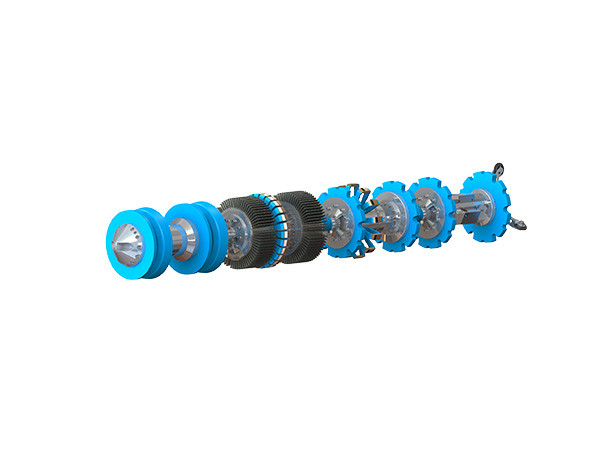

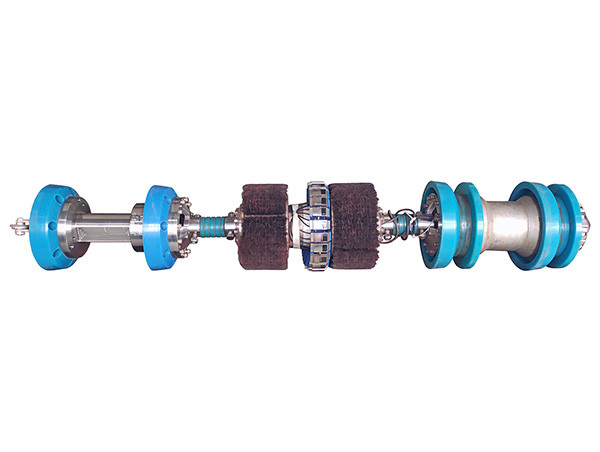

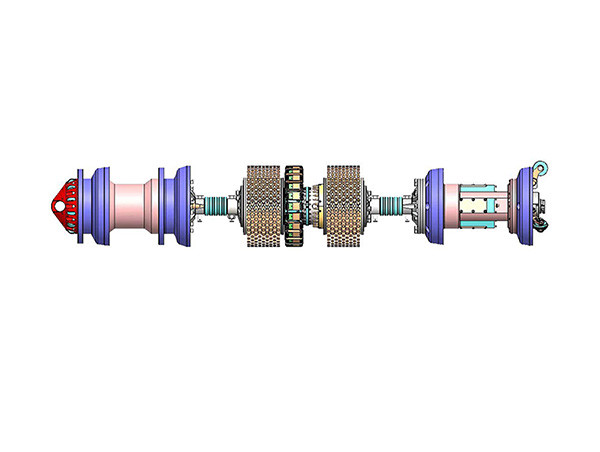

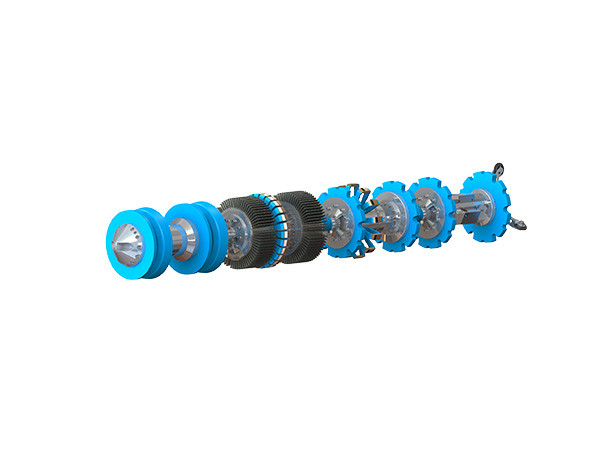

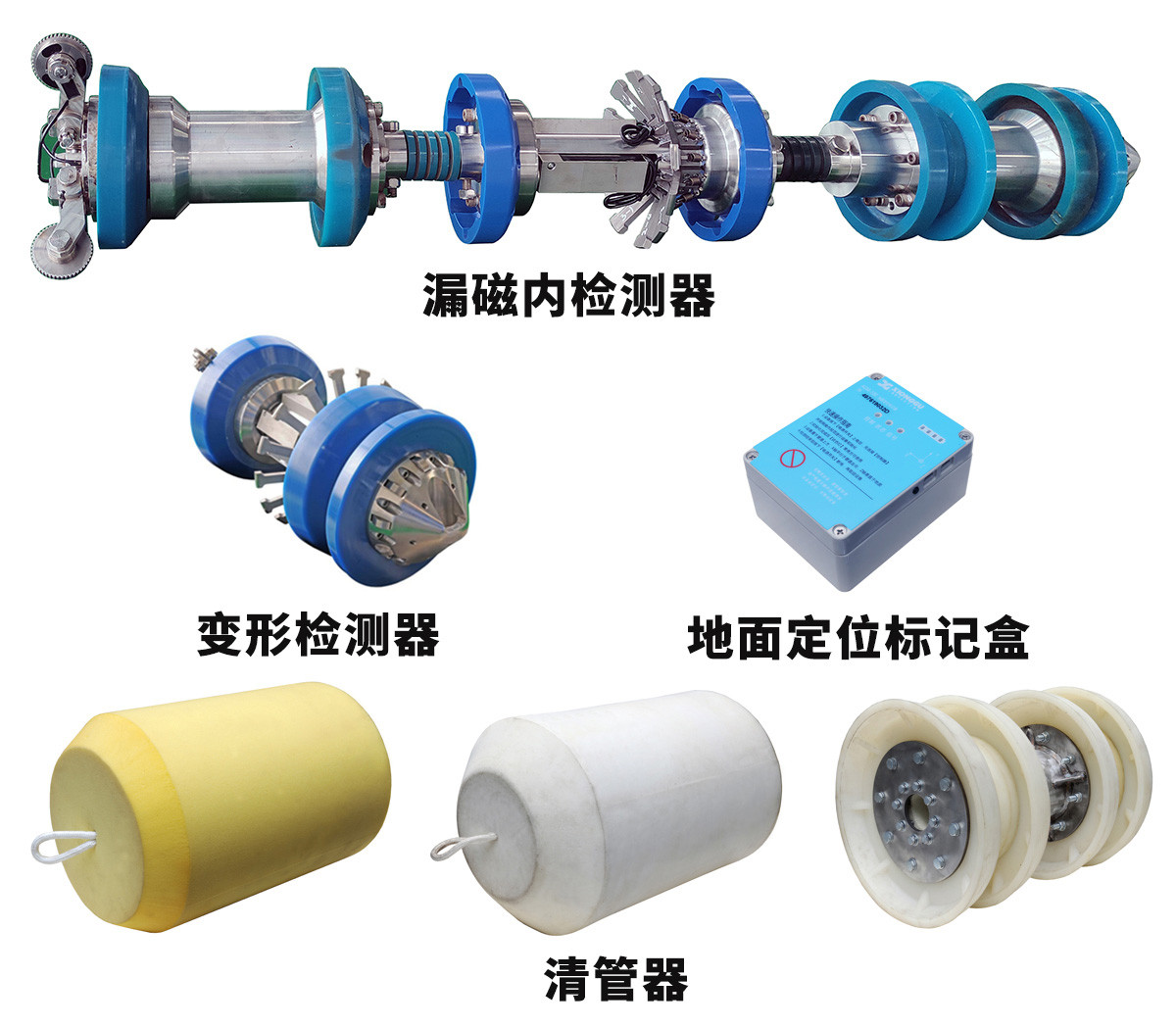

Configuration: power section, detection section, mileage section, battery, low-frequency transmitter, receiver, inertial navigation system (optional), stress detection (optional).

◆ Independently developed, brand-new ultra-high-definition three-axis magnetic flux leakage internal inspection.

◆ Rapid detection capability of more than 10m/s to improve the adaptability of natural gas pipelines;

◆ Axial sampling spacing is less than 0.5mm;

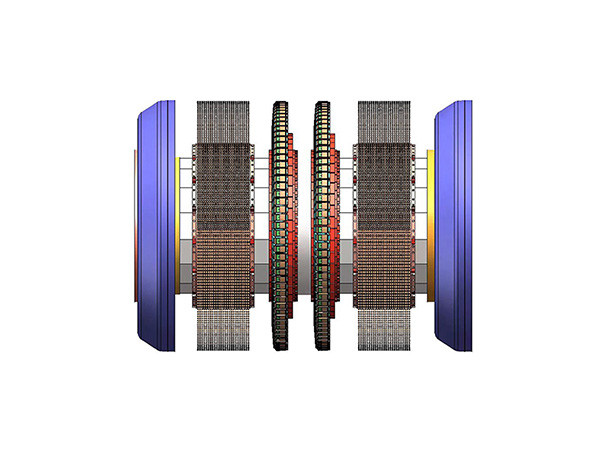

◆ The circumferential channel of the pipeline is fully covered without omission, with 0 clearance;

◆ Redundant design: double insurance independent sensor.

| The name of the metric | MI168 | MI219 | MI273 | MI323 | MI508 | MI1016 | |

| Number of detector sections | 4 | 3 | 2 | 1 | |||

| Detector length (mm) | 1540 | 1410 | 1680 | 1700 | 1850 | 1950 | |

| Detector weight (kg) | 56 | 82.5 | 161 | 200 | 450 | 2600 | |

| Wall thickness range (mm) | ≤10 | ≤10 | ≤12 | ≤12 | ≤14 | ≤20 | |

| Minimal elbow | 2.5D | 2.5D | 2.5D | 1.5D | 1.5D | 1.5D | |

| Through the ability to shapeshift | 15% | 15% | 15% | 15% | 15% | 20% | |

| working hours | 24 | 48 | 96 | 96 | 96 | 48 | |

| Number of corrosion channels | >504 | >720 | >864 | >1044 | >3456 | >7056 | |

| Maximum Detection Mileage (km) | 200 (adjustable) | ||||||

| Detector composition | Power section, detection section, mileage section | ||||||

| Temperature range | -20~80℃ | ||||||

| Speed range | ≤10m/s | ||||||

| Pressure range | ≤12MPa | ||||||

| Sampling spacing | <0.5mm | ||||||

| Hoop spacing(mm) | <2 | 0 | |||||

| Bowl surplus | 1~5% | ||||||

| Number of mileage lanes | 3 | ||||||

With continuous technological advancements, the appearance, color, and parameters may change. The parameters are for reference only and are not to be used as acceptance inspection standards.

By clicking 'Agree All', you agree to the storage of cookies on your device to enhance sitenavigation, analyze site usage and assist with our marketing efforts.