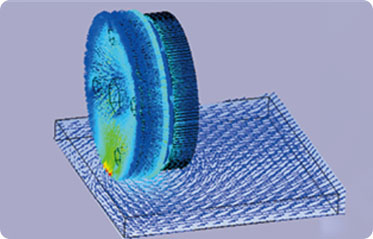

1. Magnetic suction chassis

2. Intelligent parameter planning

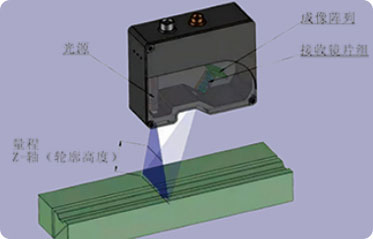

3. Laser vision tracking

4. Omni-directional expert database

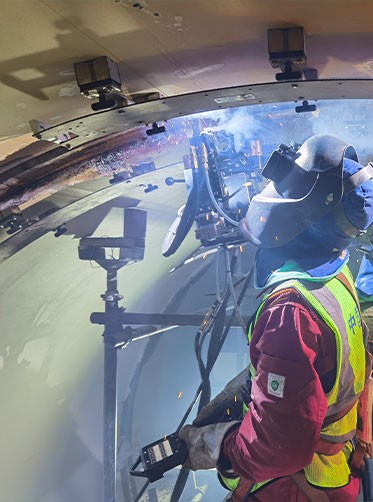

Ship welding

Ship welding

Welding of pressure steel pipes for pumped storage

Welding of pressure steel pipes for pumped storage

Welding of steel structures for ocean engineering

Welding of steel structures for ocean engineering

Pressure vessel welding

Pressure vessel welding

Tank welding

Tank welding

Featuring a magnetic chassis and innovative structural design with advanced magnetic materials, it demonstrates impressive adhesion (stably supporting 120kg) even in high-temperature environments (base material temperature of 150℃), ensuring seamless docking and convenient installation.

Equipped with dual laser vision sensors, the A-391 boasts extraordinary "vision," capable of autonomously and accurately identifying weld seam trajectories, ensuring every movement is precise. It automatically adjusts the welding gun’s position, allowing the welding process to flow smoothly, balancing efficiency and quality.

The remote control range easily covers 40 meters, with a battery life exceeding 10 hours (replaceable battery). With an IP68 rating for waterproof and dustproof certification, it stands strong against harsh environmental challenges. Weighing only 425 grams and designed with ergonomics in mind, it ensures comfortable operation. Real-time display of weld images and welding parameters makes every step of the operation clear and visible.

Innovatively combining the welding control cabinet and power supply into one unit, it completely eliminates the traditional bulky design, significantly reducing system complexity and optimizing space utilization. This integrated design not only enhances the overall aesthetics of the system but also achieves efficient data interaction, making the welding process smoother and management and maintenance more convenient.

Talk to our welding experts and uncover the solutions tailored to your needs. We offer high-quality welding services and equipment that can enhance performance even in the toughest manufacturing and construction environments. Please feel free to contact us to discuss your project.

By clicking 'Agree All', you agree to the storage of cookies on your device to enhance sitenavigation, analyze site usage and assist with our marketing efforts.