Product Introduction

-

-

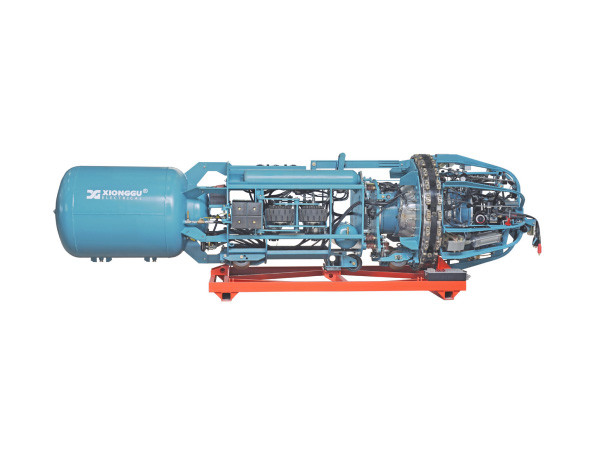

MD-550 Diesel Engine Driven Multi-process Welder

Function:

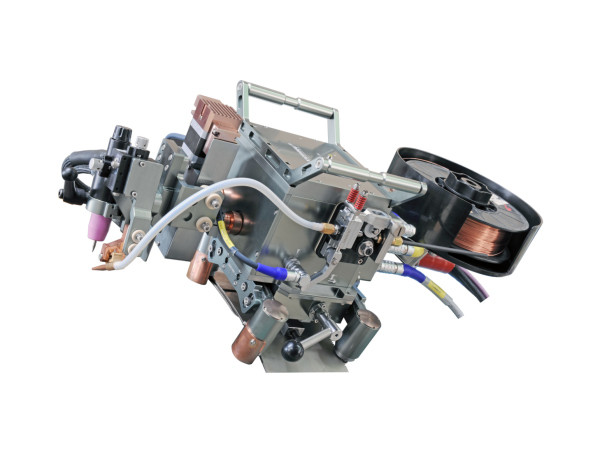

GTAW (lift arc), SMAW

Model A: GMAW, FCAW-GS, FCAW-SS, carbon arc gouging

Product promotion video

Product parameters

| Model | MD-550 | |

| Product ID | 4128000000 | |

| Welder Output | ||

| Electrode Holder | A | B |

| Rated Output Current/Voltage |

200A/28V(SMAW) 270A/20.8V(GTAW)400A/36V(FCAW) |

200A/28V(SMAW) 270A/20.8V(GTAW) |

| Rated Duty Cycle | 60% | |

| Max. Open-Circuit Voltage(Peak) | 87V | |

| Output Current Range |

20~200A(SMAW) 20~275A(GTAW) 20~400A(Only A) |

20~200A(SMAW) 20~275A(GTAW) |

| Output VoltageRange | 17~34V(CV) | / |

| Engine、Generator | ||

| Auxiliary Power | 1×380V/17kVA/50/60Hz | |

| 2×220V/2kVA /50/60Hz | ||

| Engine Model | Perkins 404D-22 | |

| Engine Rated Output Power | 22kW | |

| Load Fuel Consumption | ≤0.292L/kWh | |

| Fuel Tank Capacity | 70L | |

| Displacement | 2.216L | |

| Cooling | Watercooled | |

| Others | ||

| Ambient Temperature | -10℃~+40℃ | |

| Altitude |

≤1000m (If the altitude is greater than 1000m, the duty circle will decrease) |

|

| IP Rating | IP23 | |

| Insulation Grade | F | |

| Weight | 600kg | |

| Dimensions(W×L×H) | 810mm×1700mm×1120mm | |

Features & Main Technical Parameters

◆ Double welding power sources, two welding outputs by one machine;

◆ Diesel engine driven, one click operation, microcomputer monitoring, automatic protection and alarm;

◆ Data acquisition and transmission system, supporting WIFI, 4G, etc.

◆ High performance DSP chip is used for power source and arc control, precise control of droplet transfer, reduction of spatter, strong product consistency;

◆ Good human-computer interactive operation interface, convenient unified adjustment, and multiple sets of process parameters are stored for calling;

◆ Lift arc striking arc when GTAW process is applied, which does not generate high frequency voltage and has no electromagnetic interference;

◆ The built-in unified parameter expert database system will automatically call the best welding process parameters when regulating only welding current;

◆ It has a good welding experience of wide regulation range of welding parameters, minimal spatters, stable arc and good adaptability to extended wire length;

◆ Min. welding current 70A when GMAW process is applied, stable and reliable welding, arc energy concentration, deep penetration;

◆ The speed of slow wire feeding can be adjusted to ensure the success rate of arc starting; the parameters of arc starting can be adjusted to ensure the appropriate parameters of arc starting and reduce defects;

◆ The parameters of arc stopping are adjustable, with the function of removing molten ball when stopping arc so as to avoid the risk of molten ball at the end of wire and wire sticking caused by arc stopping;

◆ Automatic welding controller interface and robot control interface are available to realize automatic welding.