Product Introduction

-

-

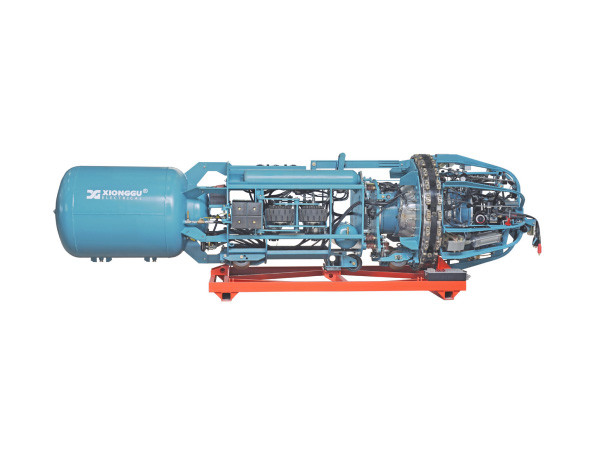

MD-1100 CC/CV diesel engine driven digitalized pipeline welding

MD-1100 CC/CV diesel engine driven digitalized pipeline welding workstation ("the workstation" for short thereinafter) is a kind of double-handle (welding is carried out at two working positions at the same time) welding equipment with four welding functions applicable for welding construction without power supply in the field. The protection level of housing of the workstation is IP23, and it can be used on the condition that the inclination angle caught in the rain≤60° (Relative to all the vertical planes of the workstation)

Product parameters

| Model | MD-1100CC/CV |

| Ratedoutputcurrent/voltage | 2groups400A/36V |

| Rateddutycycle | 60% |

| MAX.Open-circuitvoltage | 83V |

| Voltageregulationrange(CV) | 17.5V/70A—34V/400A |

| Currentregulationrange(CC) | 50A/22V—400A/36V |

|

Engine Rated Output Power |

50kW |

| Revolvingspeed | 1500r/min(Rated,high-speed) |

| 800-1050r/min(Idlingspeed) | |

| Fuelcapacity | 80L |

| Dieselengine | DongfengCummins4BTA3.9-G2 |

| Dieselmodel | No.0dieselat normaltemperature(SeeTable10forreference) |

| Modelofmachineoil |

Machineoilofdiesel engineaboveCF level (Selected accordingto environmentandatmospherictemperature,seeTable5for reference) |

| Pressureofmachineoil | ≥207kPa(Highspeed) |

| ≥69kPa(Idlingspeed) | |

| Oil capacity | 9.5L |

|

Availablemaximumtemperatureof coolingliquid |

≤95℃ |

| Protectionlevel ofhousing | IP23 |

| Volume | 1900×900×1576mm(Notrailer) |

| Netweight | 1000kg(Notrailer) |

Features & Main Technical Parameters

◆ The overseas famous brand diesel engine and power generator are taken, which features high reliability and low operating cost.

◆ It is the double-handle welding equipment for two working positions to carry out welding at the same time, and has the functions including self-shielded flux-cored wire semi-automatic welding, cellulose electrode downward welding, low-carbon electrode downward welding, general manual electrode arc welding, argon shielded arc welding and etc.

◆ It has the auxiliary power output with the maximum output power of 30kVA 60Hz.

◆ The control system with microcontroller as the core is taken to monitor the operating condition of diesel engine, and protect diesel engine reliably.

◆ The IGBT module and PWM control technology are taken. The inverter frequency reaches 20KHz, and the dynamic performance is good.

◆ The negative feedback control is taken. It features constant flat characteristic voltage, constant falling characteristic current, stable welding procedure, easy control of weld pool,easy arc strike, stable arc, small spatter and good weld form.

◆ No-load voltage is automatically matched according to different output characteristics: The no-load voltage in time of semi-automatic flux-cored self-shielded welding is 45V, and the voltage in time of manual welding is 75V.

◆ Welding current and voltage are shown in digital display. The welding current of manual welding can be preset or adjusted ampere by ampere (1A).

◆ Manual welding has the function to adjust arc striking current and thrust current.

◆ The switch of semi-automatic welding gun takes the self-locking mode, which reduces the labor intensity of welders.

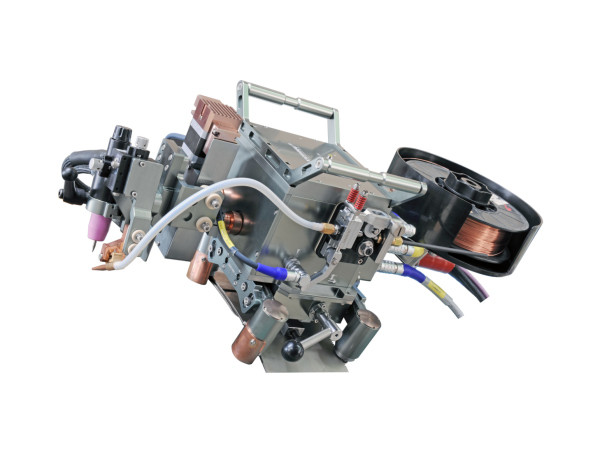

◆ In time of semi-automatic welding, the adjusting knob of welding parameters is set on wire feeder; the adjusting knob of welding current in manual welding is set on power source. It features convenient operation.

◆ The workstation is equipped with complete and advanced supporting facilities, and the connection is simple and reliable.

On-site use