Product Introduction

-

-

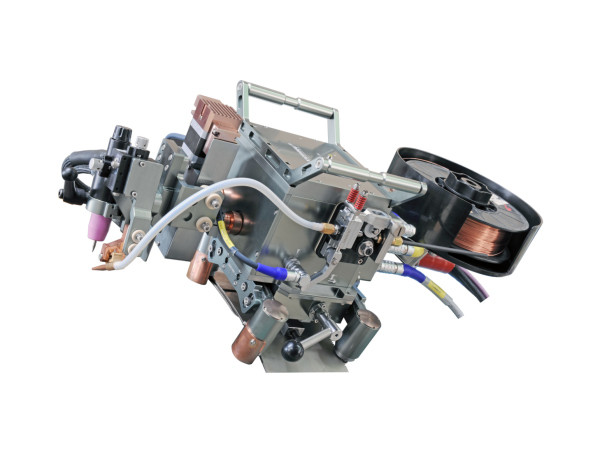

A-610 All Position Dual Torch Pipeline Automatic Welding Machine

Function:

It can be used for hot pass, fill & capping welding of pipeline. GMAW-S and GMAW-P and FCAW-GS welding processes can be applied.

Configuration:

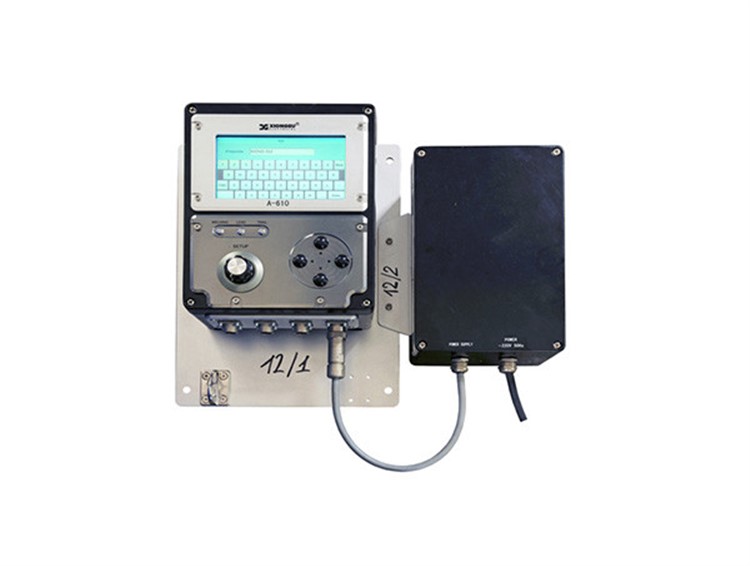

Welding head, wire feeder, central controller, LCD portable panel, welding power source, water cooler, water cooling torch, control cables.

Product characteristics

◆LCD portable panel with display available in Chinese/English, convenient and intuitive.

◆Designed with welding seam arc tracking in both vertical and horizontal axis, reduce welder's operation difficulties and labor intensity.

◆Embedded system is applied, welding expert database is built-in, corresponding welding parameters can be called according to the access level.

◆The system can automatically call the corresponding parameters according to the position of the welding head, smooth transition of welding parameters in each layer and accurate all position welding can be realized.

◆4G mobile web, WIFI and QR code scanning interfaces are reserved, it can provide remote technical services and data cloud transmission to facilitate real-time quality management.

Product promotion video

Product parameters

| Model | A-610 |

| ApplicablePipe Diameter | ≥Φ500 mm |

| Travel Speed | 0.1~1.55 m/min |

| Wire Feeding Speed | 2.5~25 m/min |

| Torch Oscillation Mode | Double torches separate oscillation |

| Torch Angle | ± 10° |

| Torch Vertical Movement | 50.8mm |

| Torch Horizontal Movement | 50.8mm |

| Ambient Temperature | -40~55℃ |

| Altitude | 4500m |

| Ingress Protection | IP54 |

| Weight of Welding Head | 15.8kg |

| Dimensions (W×L×H) | 345mm×400mm×390mm |