Product Introduction

-

-

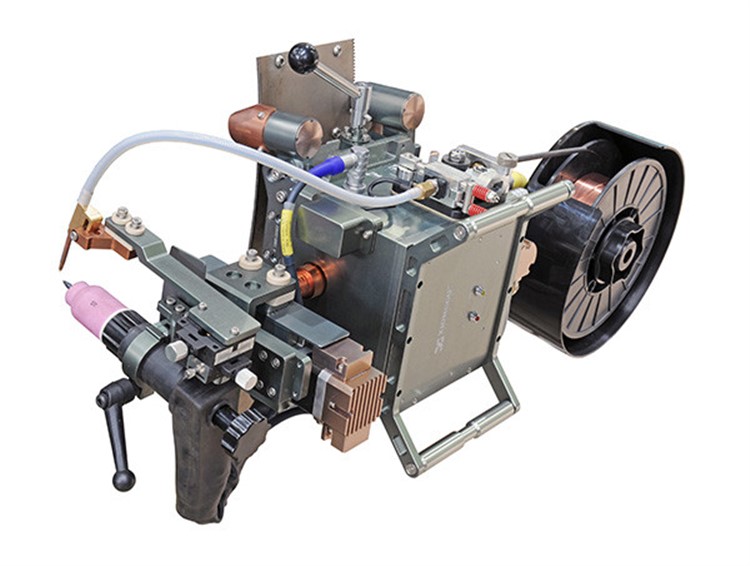

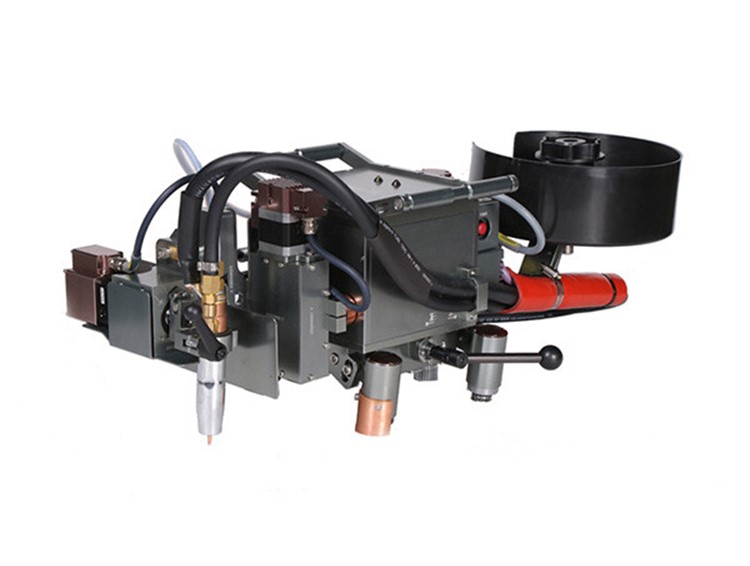

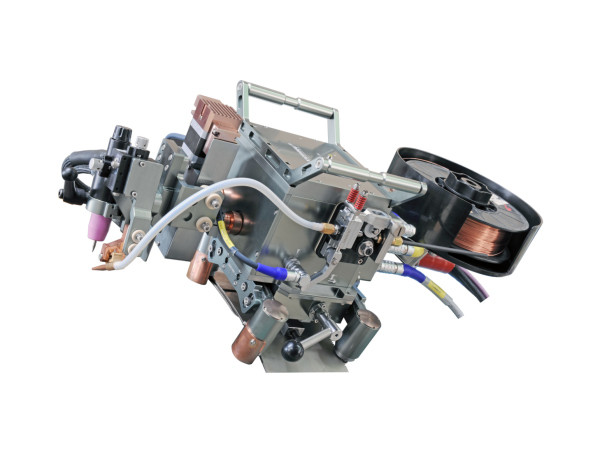

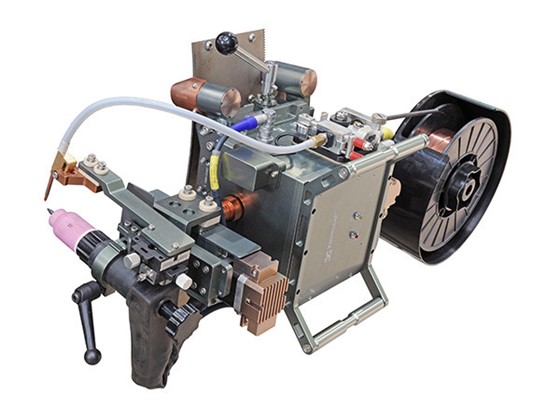

A-305 All Position Pipeline Automatic Welding Machine

Function:

It can be used for root pass, hot pass, fill & capping welding of pipeline, vertical and horizontal welding of tanks. GMAW and FCAW-GS welding processes can be applied. All position welding of various workpieces can be realized if various tracks are applied.

Configuration:

Welding head, LCD portable panel, control cables, digital welding power source (built-in controller).

Product characteristics

◆Chinese/English display.

◆The height of the welding head is lower, which is more suitable for the welding in narrow space such as prefabrication of pipeline in refinery plant and urban pipeline construction.

◆Operated via LCD portable panel, convenient and intuitive, reduce the welder's labor intensity.

◆Built-in welding expert database, corresponding welding parameters can be modified and called according to the access level.

◆Smooth transition of welding parameters in each layer and accurate all position welding can be realized.

◆4G mobile web, WiFi and QR code scanning interfaces are reserved; it can provide remote technical services and data cloud transmission to facilitate real-time quality management.

◆With welding seam arc tracking function when GMAW with solid wire process is applied.

◆1G, 2G, 3G, 4G, 5G, 5GX, 6G and 6GX welding can be realized by applying different tracks.

Product promotion video

Product parameters

| Model | A-305 |

| Applicable Pipe Diameter | ≥Φ168mm |

| Travel Speed | 0.1~1.5 m/min |

| Wire Feeding Speed | 2.5~16 m/min |

| Number of Sectionper Group | 1~180 Sections |

| Torch Oscillation Width | 0~50.8mm |

| Torch Oscillation Mode | Linear/pendular |

| Torch Vertical Movement | 0~ 50.8mm |

| Torch Horizontal Movement | 0~50.8mm |

| Torch Inclination Angle | ±45° |

| Weight of Wire Spool | 5kg |

| Ambient Temperature | -40~55℃ |

| Altitude | 4500m |

| IP Rating | IP54 |

| Weight | 15.8kg |

| Dimensions(L×W×H) | 600mm×350mm×250mm |